Valves & Faucets

Willoughby offers a variety of pneumatic and electronic valves, as well as faucets. All valves have machined stainless steel pushbuttons and escutcheons, including the piezoelectric actuators. Manifolding is available with some valves, which can reduce installation costs.

Download forms and marketing literature »

Filter by Tag

Showing all 16 results

-

LRFC Ligature-Resistant Infrared Faucet

The Willoughby LRFC Ligature-Resistant, Infrared Faucet—constructed from cast 304 stainless steel—is recommended for high-use areas where risk accommodations are a concern, such as behavioral and mental health facilities. These faucets feature a contoured design and IR sensor with preset, elapsed time lockouts to minimize vandalism and, with the 4” center set, are ready for new construction projects or retrofitting existing lavatories. The LRFC comes with all the necessary mounting hardware to install on lavatories and provide a water-tight seal, along with a battery-operated or hard-wired valve and power supply. Additionally, there is a serviceable insert—with a spray pattern flow and smart lime cleaning technology—that provides additional protection against vandalism. All faucets offer a 35° angle of spray with a 16° maximum swivel adjustment and a maximum flow rate of 0.5 GPM. -

LRFC-PBH Ligature-Resistant Pneumatic Push Button Faucet

The Willoughby LRFC-PBH Ligature-Resistant, Pneumatic Push Button Faucet—constructed from cast 304 stainless steel—is recommended for high-use areas where risk accommodations are a concern, such as behavioral and mental health facilities. These faucets feature a contoured design to minimize any potential ligature points and, with the 4” center set, are ready for new construction projects or retrofitting existing lavatories. The LRFC-PBH comes with all the necessary mounting hardware to install on lavatories and provide a water-tight seal. Additionally, there is a serviceable insert—with a spray pattern flow and smart lime cleaning technology—that provides additional protection against vandalism. All faucets offer a 35° angle of spray with a 16° maximum swivel adjustment and a maximum flow rate of 0.5 GPM. -

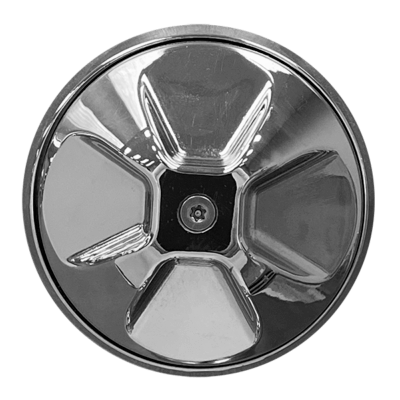

LRFC-PZPB Ligature-Resistant Piezo Electronic Push Button Faucet

The Willoughby LRFC-PZPB Ligature-Resistant, Piezo Electronic Push Button Faucet—constructed from cast 304 stainless steel—is recommended for high-use areas where risk accommodations are a concern, such as behavioral and mental health facilities. These faucets feature a contoured design to minimize any potential ligature points and, with the 4” center set, are ready for new construction projects or retrofitting existing lavatories. The LRFC-PZPB comes with all the necessary mounting hardware to install on lavatories and provide a water-tight seal. Additionally, there is a serviceable insert—with a spray pattern flow and smart lime cleaning technology—that provides additional protection against vandalism. All faucets offer a 35° angle of spray with a 16° maximum swivel adjustment and a maximum flow rate of 0.5 GPM. -

PML-BHF Valve

The Willoughby PML-BHF Lead-Free, Behavioral Health Pneumatic Faucet is a ligature-resistant water control valve for use with plumbing fixtures in security, commercial, and healthcare environments. They are designed to replace existing valves on china and aluminum fixtures without integral bubblers, and can be specified in either Single Temp. (PML1-BHF) or Dual Temp. (PML2-BHF) configuration. Standard PML-BHF valve assemblies are made from components complying with NSF-61, and will typically come with stainless steel push buttons, stainless steel bubbler, pneumatic tubing and fittings, and associated plumbing connections. The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.), recommended with a max. operation temperature of 110° Fahrenheit, and supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. Both PML1-BHF and PML1-BHF valve assemblies can be supplied with an optional thermostatic mixing valve. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

DVLR Ligature-Resistant Diverter Valve

The Willoughby DVLR Ligature-Resistant Diverter Valve Assembly is for use with plumbing fixtures in security, commercial, and healthcare environments. Standard DVLR valve assemblies are chrome-plated, die-cast construction. The valve assembly is designed for operational pressure between 35-70 psi, and the inlet connection is 3/8” P.T.C. and the outlet connections is 3/8” P.T.C. -

TPLR Ligature-Resistant Mixing Valve

The Willoughby TPLR Ligature-Resistant, Temperature and Pressure Mixing Valve Assembly is a self-contained mixing valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard TPLR valve assemblies are chrome-plated, die-cast construction. The valve assembly is designed for operational pressure between 35-70 psi, 90 psi max., and the inlet connection is 3/8” M.P.T. and the outlet connection is 3/8” M.P.T. -

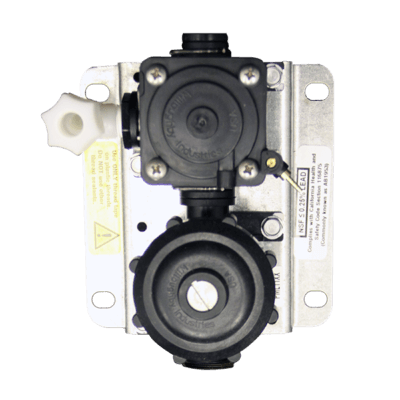

PML1/PSL1 Pneumatic Valve

Willoughby PML1 and PSL1 Single Temperature, Lead-free, Pneumatic Valves are water control valves for use with plumbing fixtures in security, commercial, and healthcare environments. Pneumatic control valves can be specified in either Metering (PML1) or Non-metering (PSL1) configurations. Standard PML1 and PSL1 valve assemblies are made from components complying with NSF-61, and will typically come with selected stainless steel push button(s), pneumatic tubing and fittings, and associated plumbing connections. The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.), recommended with a max. operation temperature of 110° Fahrenheit, and supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. Both the PML1 and PSL1 valve assemblies can be supplied with a variety of optional features including: flow control, push button(s), thermostatic mixing valve, etc. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

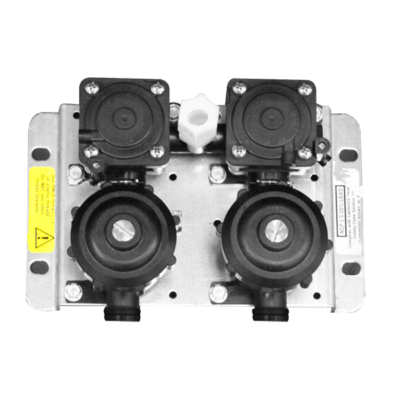

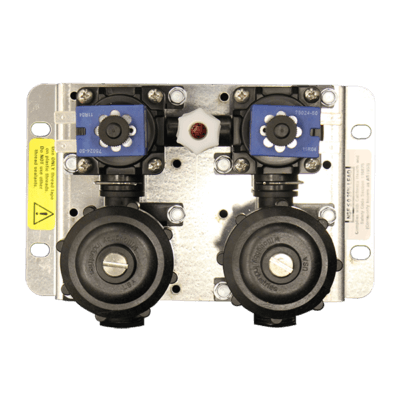

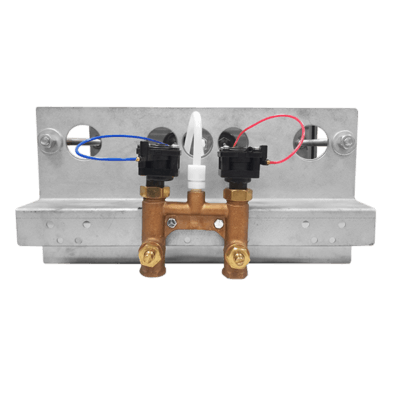

PML2/PSL2 Pneumatic Valve

The Willoughby PML2 and PSL2 Dual Temperature, Lead-free, Stainless Steel Pneumatic Valve Assemblies are water control valves for use with plumbing fixtures in security, commercial, and healthcare environments. They can be specified in either Metering (PML2) or Non-metering (PSL2) configurations. Standard PML2 and PSL2 valve assemblies are made from components complying with NSF-61, and will typically come with selected stainless steel push buttons, pneumatic tubing and fittings, and associated plumbing connections. The dual temperature valve allows the user to select hot water or cold water, or combine both; however, the hot side of the valve must be supplied with tempered water to ensure proper operation and user safety (recommended with a max. operation temperature of 110° Fahrenheit). The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.) and is supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. Both the PML2 and PSL2 valve assemblies can be supplied with a variety of optional features including: flow control, push buttons, thermostatic mixing valve, etc. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

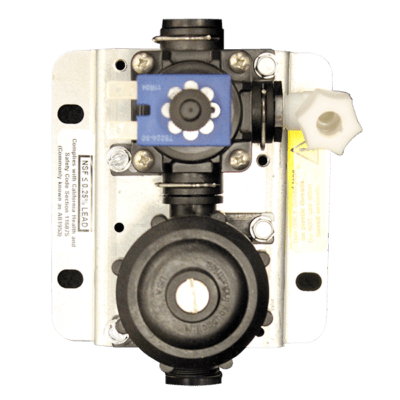

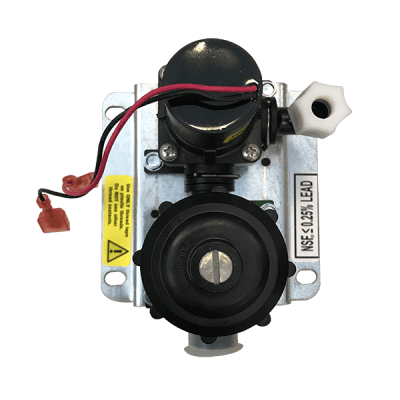

E1L1 Electronic Valve

The Willoughby E1L1 Single Temperature, Lead-free, Electronic Control Valve Assembly is a water control valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard E1L1 valve assemblies are made from components complying with NSF-61, and will typically come with selected stainless steel push button(s), specified electronic control, and associated plumbing connections. The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.), recommended with a max. operation temperature of 110° Fahrenheit, and supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. The E1L1 valve assembly can be supplied with a variety of optional features including: flow control, electronic control, push button(s), thermostatic mixing valve, etc. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

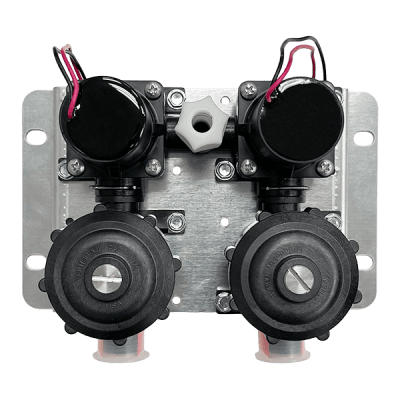

E1L2 Electronic Valve

The Willoughby E1L2 Dual Temperature, Lead-free, Electronic Valve Assembly is an electronic water control valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard E1L2 valve assemblies are made from components complying with NSF-61, and will typically come with selected stainless steel push buttons, specified electronic control, and associated plumbing connections. The dual temperature valve allows the user to select hot water or cold water, or combine both; however, the hot side of the valve must be supplied with tempered water to ensure proper operation and user safety (recommended with a max. operation temperature of 110° Fahrenheit). The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.) and is supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. The E1L2 valve assembly can be supplied with a variety of optional features including: flow control, electronic control, push buttons, etc. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

EBL1 Electronic Valve (Battery)

The Willoughby EBL1 Battery Operated, Single Temperature, Lead-free, Electronic Valve Assembly is a water control valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard EBL1 valve assemblies are made from components complying with NSF-61, and will typically come with an infrared sensor(s), 6V DC battery pack, and associated plumbing connections. The valve assembly is designed for operational pressure between 35-60 psi, recommended with a max. operation temperature of 110° Fahrenheit, and supplied with an appropriate flex hose (1/2” F.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. Each sensor-activated, latching valve will require an individual battery pack, using (6) AA-Type batteries, provided by the manufacturer. The EBL1 valve assembly can be supplied with optional features and configurations. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

EBL2 Electronic Valve (Battery)

The Willoughby EBL2 Battery Operated, Dual Temperature, Lead-free, Electronic Valve Assembly is a water control valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard EBL2 valve assemblies are made from components complying with NSF-61, and will typically come with an infrared sensor(s), two 9V DC battery packs, and associated plumbing connections. The valve assembly is designed for operational pressure between 35-60 psi, recommended with a max. operation temperature of 110° Fahrenheit, and supplied with an appropriate flex hose (1/2” M.P.T.) to connect to the operational water supply. Flex hose is supplied standard unless otherwise specified. Each sensor-activated, latching valve will require an individual battery pack, using (6) AA-Type batteries, provided by the manufacturer. The EBL2 valve assembly can be supplied with optional features and configurations. A galvanized mounting plate is provided for secure anchoring of the valve assembly (anchoring hardware by others). -

T4 Toilet Overflow Preventer

The Willoughby T4 Toilet Overflow Preventer, w/ Manual Reset, is a self-contained water sensor valve setup for use with specially modified Willoughby toilet fixtures installed in high vandalism environments. The sensor/valve setup is designed to disallow the overflowing of toilet bowls. The T4 overflow preventer system consists of a vacuum operated disabler (T-4 valve), a vacuum generator (welded to the modified toilet fixture), overflow sensor (also welded), and connecting tubing. The system operates on vacuum produced by water flowing through the fixture. When the vacuum can move unrestricted through the overflow sensor, the disabler valve remains open; but when water is drawn into the sensor as a result of a clog or blockage in the fixture, the vacuum will close the disabler valve, preventing any additional flushing. Once the disabler valve has closed, the toilet will not flush until the disabler valve has been manually reset. The T4 overflow preventer system is recommended for facilities with high risk for vandalism, such as prisons, schools, parks, etc., and can be used with most models of Willoughby back-supply toilets and combination units provided with an accessible mechanical chase. -

T4A Toilet Overflow Preventer

The Willoughby T4A Toilet Overflow Preventer, w/ Auto-Reset, is a self-contained water sensor valve setup for use with specially modified Willoughby toilet fixtures installed in high vandalism environments. The sensor/valve setup is designed to disallow the overflowing of toilet bowls. The T4A auto-reset overflow preventer system consists of a vacuum operated disabler (T-4 valve), a vacuum generator (welded to the modified toilet fixture), overflow sensor (also welded), float sensor canister, and connecting tubing. The system operates on vacuum produced by water flowing through the fixture. When the vacuum can move unrestricted through the overflow sensor, the disabler valve remains open; but when water is drawn into the sensor as a result of a clog or blockage in the fixture, the water will be drawn into the float canister. As the float canister fills, the float inside the canister rises and redirects the vacuum, closing the disabler valve and preventing any additional flushing. Once the disabler valve has closed, the toilet will not flush until the water level in the toilet bowl falls below the overflow sensor, allowing the water in the float canister to drain, redirecting the vacuum to reopen the disabler valve. The T4A auto-reset overflow preventer system is recommended for facilities with high risk for vandalism, such as prisons, schools, parks, etc., and can be used with most models of Willoughby back-supply toilets and combination units provided with a (preferably accessible) mechanical chase. -

SVC/DVC Compression Valve

The Willoughby SVC/DVC Single Temperature Compression Valve / Dual Temperature Compression Valve is a self-contained water supply valve for use with plumbing fixtures in security, commercial, and healthcare environments. Standard SVC/DVC valve assemblies are made from stainless steel and brass components, and will typically come with a vandal resistant stainless steel knurled knob. The valve is supplied with an appropriate flex hose (3/8” F.P.T.) inlet and a 3/8” M.P.T outlet. (Flex hose is supplied standard unless otherwise specified.) -

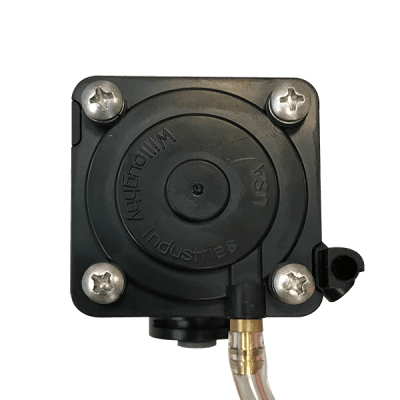

WRMV/WRSCV Valve

The Willoughby WRMV and WRSCV Retrofit Pneumatic Valve Assemblies are self-contained valve cartridges designed to convert plumbing fixtures from mechanical, pushrod, or toggle valves to pneumatic operation. The valve cartridges are designed to fit into existing brass lavatory castings and are direct replacements for Willoughby mechanical valves manufactured after 1985. WRMV and WRSCV retrofit valves can be specified in Single Temp. Metering (WRMV-1B), Dual Temp. Metering (WRMV-2B), Single Temp. Non-metering (WRSCV-1B), or Dual Temp. Non-metering (WRSCV-2B) configurations. Standard WRMV and WRSCV valve assemblies will typically come with push button assemblies, pneumatic tubing and fittings, and applicable pneumatic cartridges. The valve assembly is designed for operational pressure between 35-70 psi (90 psi max.) and recommended with a max. operation temperature of 110° Fahrenheit.